Bronze Process

The Secret Garden in the Making by Sculptor Jason Napier

https://www.youtube.com/watch?v=IxnwABi6yE4

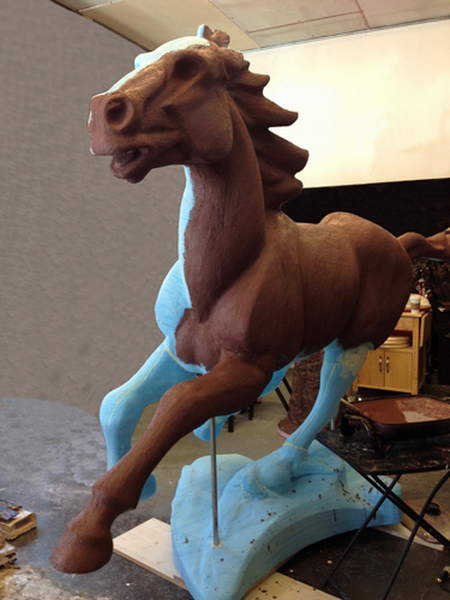

“Stir’d Up” – Lifesize Stallion

From Conception through Completion… In 2013, Jason began the process of creating this magnificent Lifesize Stallion. The sculpting process began by creating a strong metal armature with foam filler, then layer by layer, oil based clay is applied. Once the desired clay thickness is achieved, Jason uses various sculpting tools to refine and add detail. The completed original is then cut into specific sections in preparation for the casting process.

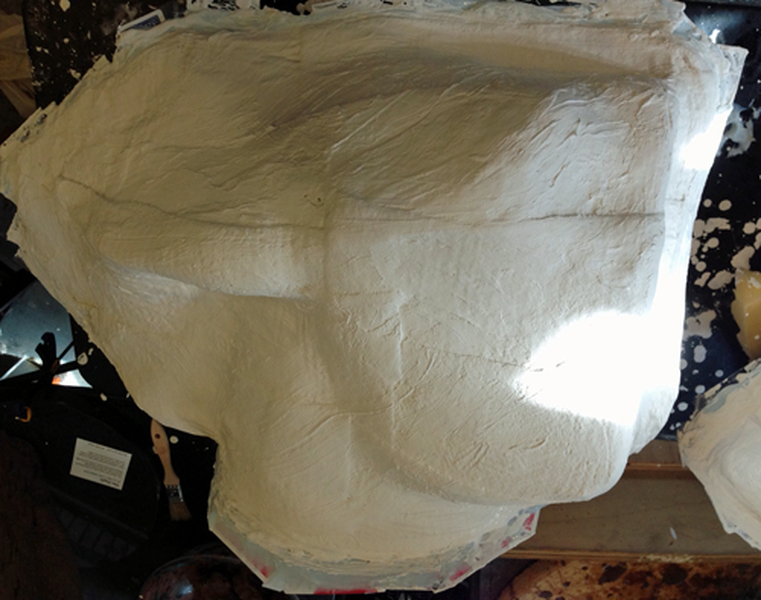

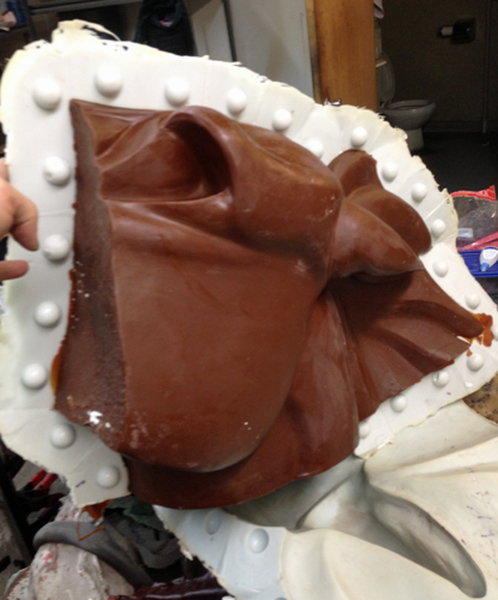

Silicon Rubber is applied in thin layers over each clay section and parted with wax cards for mold separation. A “mother mold” is then formed over the final layer of rubber for support. Each rubber mold is then separated from the clay and staged.

Layers of hot wax is then poured into the rubber molds and swished around until a 1/4″ thick coating is achieved. Once cooled, the wax pattern is carefully extracted from the rubber mold and “gated”. The gated wax patterns are attached to a wax pouring cup, submerged into a vat of silica glue, then immediately coated with fine silica sand. This timely process known as “dipping” will follow with medium and course layers of silica sand, making sure each layer is cured in between. A thin layer of the hardened silica shell is then shaved off the wax cup and staged for “de-waxing”.

The shells are heated to 600 degrees Fahrenheit and de-waxed. Now vitrified, the hollow ceramic shell molds are cooled, water checked for leaks and sealed with high temp mortar. Once inspected, each shell will be pre-heated and secured in a sand casting pit. The molten bronze is then carefully poured into each ceramic shell at 2100 degrees Fahrenheit. Once cooled, the ceramic shells are chipped away or sandblasted and the gating – “sprew system” is removed from the art.

Many hours are spent welding, grinding and tooling during the assembly process. Each bronze casting is tig welded together beginning at the base. Over 72 sections, including “windows” comprise this 1000lb bronze horse sculpture. After the artist has completed the final 2% and approved the metal work, the patina process will begin. Heat and chemicals are carefully applied to create a beautiful patina finish.